News

-

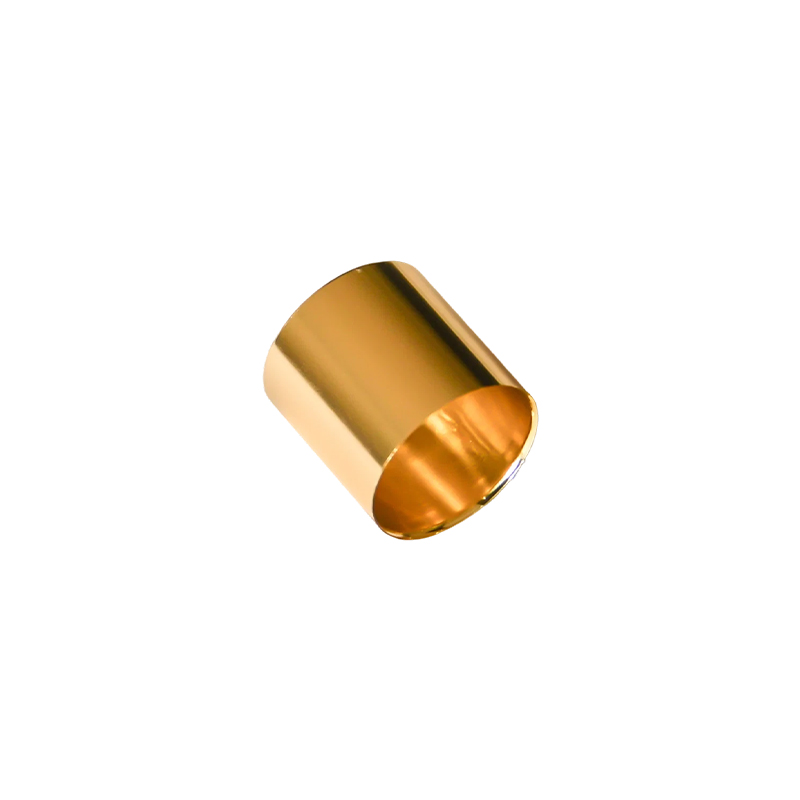

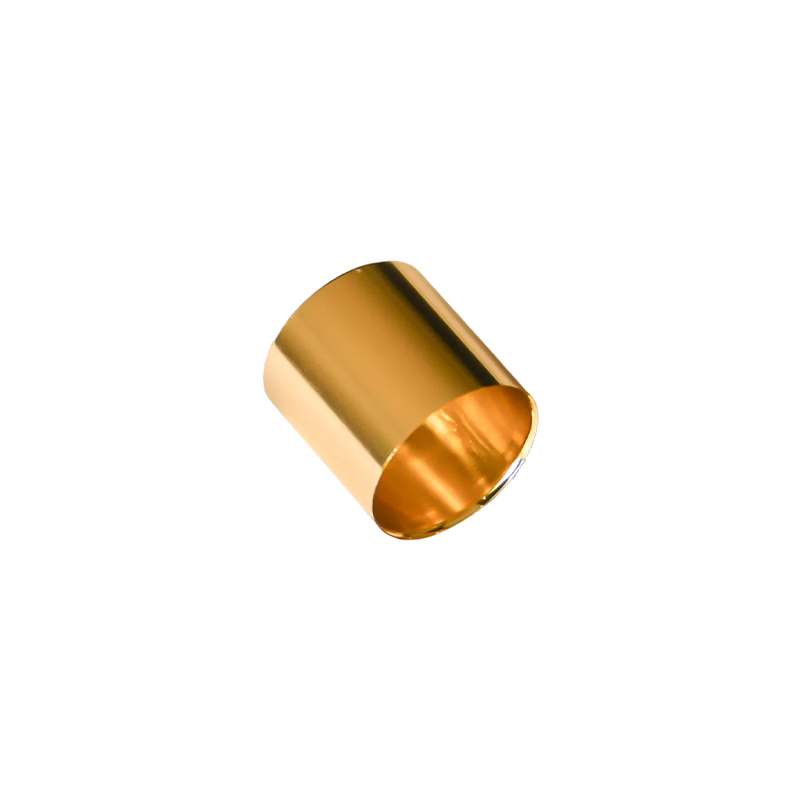

What key process parameters and steps should be paid attention to during the assembly of aluminum press cap spray nozzles?

For press caps used frequently, a short no-load run is required after assembly to ensure even distribution of grease.

Learn More2026-01-05 -

How to determine a reasonable assembly clearance between the aluminum press cap of the spray pump head and the pump body?

During assembly, ambient temperature and humidity must be controlled to avoid changes in gaps due to thermal expansion and contraction.

Learn More2025-12-22 -

How to precisely control the pressing feel of the aluminum press cap on a spray pump head?

If the pressing resistance is uneven, check whether the sealing ring is installed in place or whether there are burrs inside the pump chamber.

Learn More2025-12-08 -

How to detect internal defects in the aluminum press cap of a spray pump head?

Internal defect detection of the aluminum press cap of the spray pump head requires the comprehensive application of non-destructive testing and functional testing.

Learn More2025-11-24 -

What is the deformation recovery rate of the aluminum press cap of the spray pump head after long-term pressing?

The deformation recovery rate of the aluminum press cap of the spray pump head is the result of the combined effects of materials, structure, process and environment.

Learn More2025-11-10 -

How can aluminum press caps for spray pump heads effectively improve their overall press feel?

Compared to traditional plastic press caps, aluminum press caps for spray pump heads, with their unique physical properties and precision manufacturing, significantly enhance the overall press feel, becoming the finishing touch in high-end product packagi

Learn More2025-10-27